AMR Development

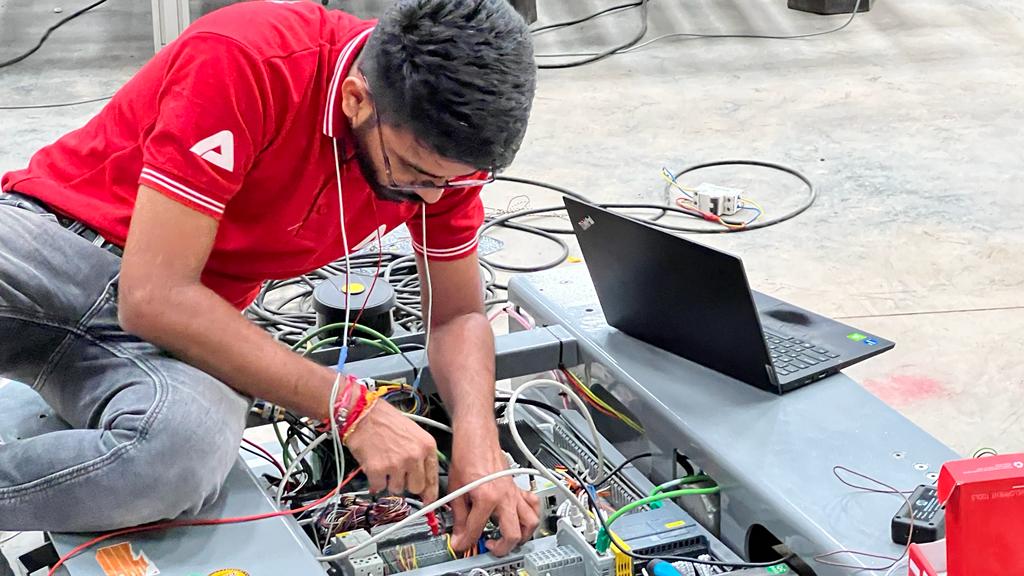

As part of this project, I was responsible for developing an in-house

AMR solution for the internal material handling process in the

industry, with a payload capacity of 1 ton.

Actions: I formed a team with other stakeholders,

including electrical, mechanical, software, and automation teams.

I defined the scope for each team member and created a project timeline

the ADER framework. My responsibilities included, but were not limited to:

- Benchmarking competitor AMRs and their specifications.

- Validating mechanical design calculations for the drive system, wheel size, battery size, weight distribution, center of gravity, etc.

- Validating electrical design calculations for the battery, motor, sensors, etc.

- Creating RFQs for vendors of motors, batteries, wheels, sensors, etc.

- Updating the design document regularly and creating the BOM (Bill of Materials) for the AMR.

- Developing the test plan for the AMR and creating test cases.

- Integrating operational and safety functionalities into the AMR.

Vision Based Depalletizer Development

As part of this project, I was responsible for developing a vision-based depalletizer for the internal material handling process in the industry.

Situation: Currently, large warehouses are transitioning from

manual depalletizing to automated depalletizing using robots. However, there are

still recurring costs to the company when it comes to changing or modifying the SKUs

or the palletizing pattern. A robotics integrator is required to modify the

taught/hardcoded program based on the SKU size and pallet pattern. This is a

time-consuming process and requires significant engineering resources.

Task: I was tasked with developing a vision-based depalletizer

that can be used for any SKU and any pallet pattern. Moreover, it needed to be a

robust system that could be deployed to any size of industrial robot and remain

immune to environmental changes.

Actions: I quickly learned the basics of programming industrial

robots using a teach pendant and understood how numerous interlocks are set to make

the system fail-safe. I also learned the basics of vision systems and benchmarked

existing vision-based depalletizer systems. I designed the architectural logic and

programmed the system using Python. For the vision system, I used YOLOv4 and

OpenCV for carton detection and cropped the background based on distance to avoid

false positives. I created a custom dataset with different SKUs, pallet patterns,

and lighting conditions.

Result: The system was able to detect cartons with 98% accuracy

achieving the required throughput. Additionally, the system successfully detected

cartons under different lighting conditions and pallet patterns.